Our SAITO KNIVES Brand are proudly handcrafted here in Brisbane by Masaaki Saito, proprietor and in-house knife master. Here is the process of how our knives are handcrafted.

Our SAITO KNIVES Brand are proudly handcrafted here in Brisbane by Masaaki Saito, proprietor and in-house knife master. Here is the process of how our knives are handcrafted.

Firstly, the quality knife steels are outlined into desired shape for rough cutting.

These are the future knives to be, roughly cut with a bandsaw.

These are the future knives to be, roughly cut with a bandsaw. These steels are annealed ( still soft before hardening process ) but still require sharp metal saw and create a big noise.

The blades are shaped more finely and smoothly using a belt grinder.

The blades are shaped more finely and smoothly using a belt grinder.We work with sparks and fire whether hot day or cold.

The blades are shaped! We use variety of steels which all have different characters so we have to be careful not to mix them up as it will affect the hardening process.

The blades are shaped! We use variety of steels which all have different characters so we have to be careful not to mix them up as it will affect the hardening process.

The blades are then marked using a steel marker with our family name " SAITO " in Japanese Kanji.

This is one of the moments that 100% focus is needed as we can't remove and redo if the logo is marked unevenly.

This is one of the moments that 100% focus is needed as we can't remove and redo if the logo is marked unevenly.

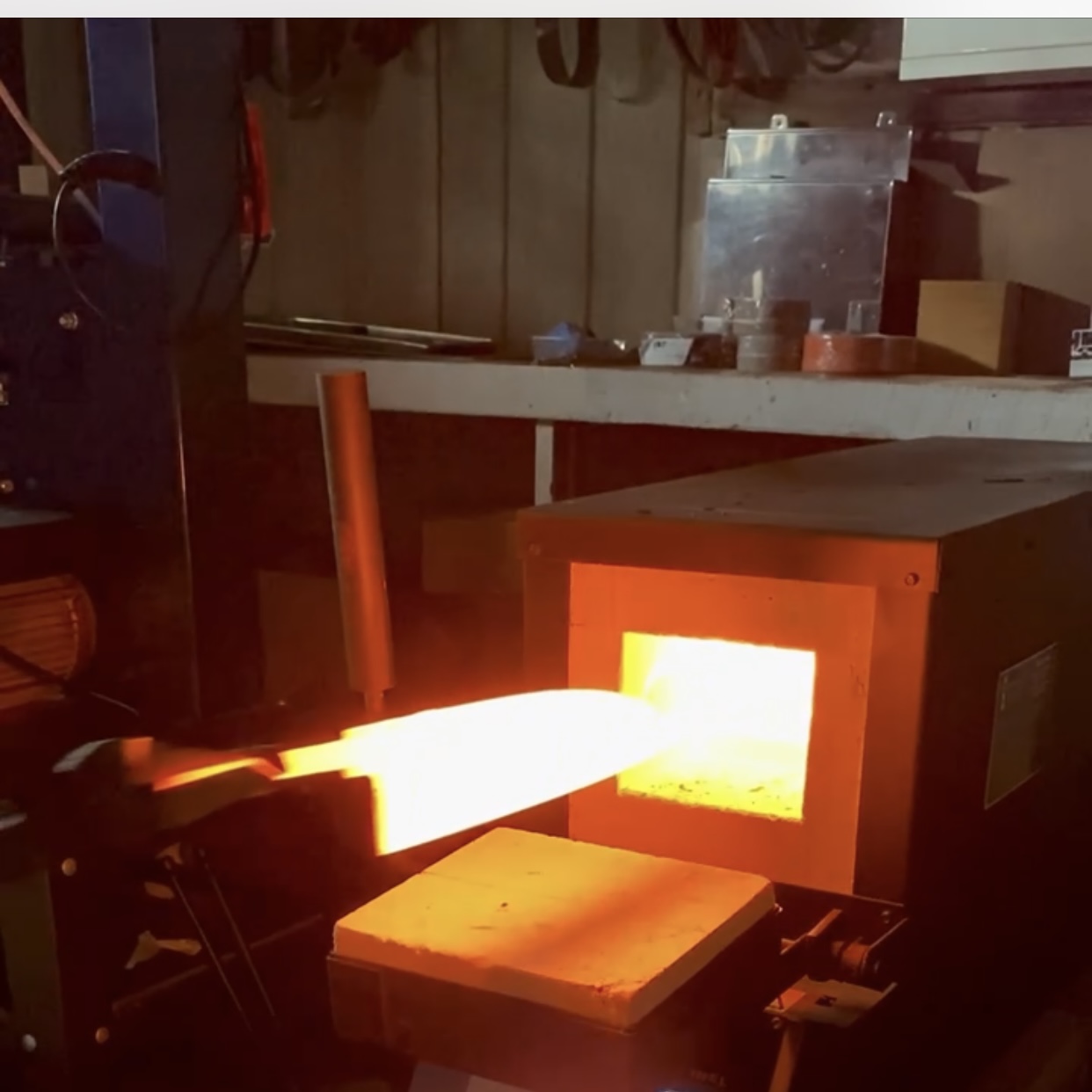

The stainless steels blades are then heated to 1050-1090c for hardening.

( High carbon steel around 750-800c )

The heat treatment determines the blade characters like hardness, brittleness and edge retention so this is definitely the most important part in knifemaking.

The heated blades are cooled down rapidly to harden and then goes into tempering cycle of 175c for approximately 2 hours to bring down the hardness a little as the quenched steels are too hard and too brittle to be used.

The heated blades are cooled down rapidly to harden and then goes into tempering cycle of 175c for approximately 2 hours to bring down the hardness a little as the quenched steels are too hard and too brittle to be used.This is a shot after all the heat treatment process.

The heat treated steels are often warped or bent from rapid temperature changes and need to be straighten by tapping with hammers.

The heat treated steels are often warped or bent from rapid temperature changes and need to be straighten by tapping with hammers.We straighten before and after the heat treatment to get them straight and extra care is put not to crack or snap them from hammering too hard.

Now moving to create bevels on each blade using a belt grinder.

Now moving to create bevels on each blade using a belt grinder.The angles depends on the purpose of the knives used for and creating right angles is another most critical part as it determines the cutting performance.

Many makers make steep angled bevels near the edge to save the time but we spend a great deal of time to taper the blade from high up towards the spine so they cut smoothly and effortlessly.

Once blades are beveled and cleaned, it's time for handle making.

Once blades are beveled and cleaned, it's time for handle making.We don't use pre-made handles for our range and each handles are made here from scratch.

We use local hardwood for most of our handles, measured, cut with a bandsaw, glued, shaped and polished.

We use local hardwood for most of our handles, measured, cut with a bandsaw, glued, shaped and polished.These unique handles give you amazing feel in your hand when gripped and add a style to your kitchen.

All handles are hand sanded and checked for any scratches before being polished with oil and food-safe wax.

All handles are hand sanded and checked for any scratches before being polished with oil and food-safe wax. Sharpening fun time!

Sharpening fun time! Knives need to be sharp and cut beautifully without a catch or slips.

We hand-sharpen every single knife using various Japanese whetstones for superior cutting experience as we know that if they don't cut well, the knives are useless no mater how beautiful they are.

Knives made with love!

Knives made with love!Nicely finished stainless steel Bunka knives with Rosewood handles to be packed and sent to our customers.

Hope they work hard at their new homes and the customers love them!